Tabletop Oxygen Analyzer for Low Levels

Item # 07-0048 Model O2L

- All Categories

- Selection by Products

- Oxygen Analyzers

- Selection by Application

- Laboratory Research

- Industrial

- Laboratory and Research

- Aerospace

- Selection by Industry

-

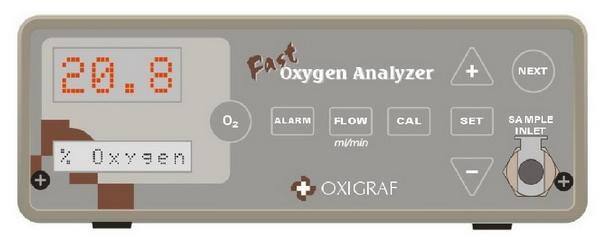

Tabletop Oxygen Analyzer for Low Levels

Item # 07-0048 Model O2L

The Model O2L analyzer is a versatile, high-accuracy oxygen analyzer designed to adapt to a wide range of measurement needs, from low-level oxygen detection to high-purity gas monitoring and process control. It measures oxygen concentrations from 0% to 100%, with 0.01% resolution for 0-10% and 0.1% from 10-100%, giving users the precision needed for their specific application. Using laser diode absorption technology, the O2L delivers fast response times, long-term stability, and smooth, interference-free readings, making it a dependable choice for industries requiring precise and consistent oxygen analysis, especially at lower concentrations.

Features

Precision Oxygen Measurement Across a Wide Range

The Model O2L is designed to measure oxygen concentrations from 0% to 100%, with an industry-leading 0.01% resolution in the 0-10% range and 0.1% resolution in the 10-100% range. This high level of precision ensures accurate oxygen analysis in critical applications such as fuel combustion efficiency, industrial process control, and pharmaceutical gas monitoring.

Low-Noise Mode (LN) for Smooth, Stable Readings

Operating in LN (Low Noise) mode, the Model O2L provides stable, interference-free readings, reducing fluctuations and ensuring smooth data acquisition. This is particularly beneficial for scientific research, medical applications, and process control environments where consistent, high-precision measurements are required.

Pressure-Independent Oxygen Measurement

Unlike many conventional sensors, the Model O2L's oxygen measurement is independent of sample pressure, ensuring accurate readings regardless of variations in gas flow or pressure changes. This makes it ideal for engine testing, fuel monitoring, and environments where pressure fluctuations are common.

Unaffected by Gas Temperature and Background Gases

The Model O2L provides consistent and accurate oxygen readings regardless of sample gas temperature or the presence of other gases, including CO₂ and H₂O. In most cases, gases other than oxygen do not affect the measurement, except for their dilution effect in a gas mixture. This makes the Model O2L ideal for combustion analysis, pharmaceutical applications, and industrial gas processing, where gas compositions frequently change.

Ultra-Fast Response Time for Immediate Process Adjustments

With a sub-150 millisecond response time, the Model O2L provides instantaneous detection of oxygen concentration changes, allowing for real-time adjustments in industrial combustion systems, food packaging processes, and laboratory experiments. This rapid feedback enhances efficiency, safety, and product quality.

Leak-Free Gas Pathway for Contaminant-Free Oxygen Analysis

The Model O2L features a sealed gas pathway, preventing external contamination and unwanted gas dilution. This is critical for applications in air separation, cryogenic gas processing, and research environments, where even minor leaks can compromise oxygen purity and measurement accuracy.

Multiple Output Options for Seamless System Integration

Featuring analog (0-1V DC, 4-20mA) and digital (RS-232) outputs, the Model O2L integrates easily into industrial automation systems, research platforms, and aerospace applications. These communication options allow for real-time monitoring and process optimization.

Technical Data