Oxygen Analyzer for Air Separation- High Altitude

Item # 07-7016 Model O2D(AL)

Item # 07-7024 Model O2D(AL)-S

- All Categories

- Selection by Products

- Oxygen Analyzers

- Selection by Application

- Laboratory Research

- Selection by Industry

- Laboratory and Research

- Medical and Healthcare

-

Oxygen Analyzer for Air Separation- High Altitude

Item # 07-7016 Model O2D(AL)

Item # 07-7024 Model O2D(AL)-S

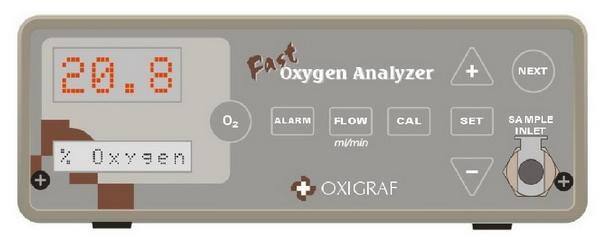

The Models O2D(AL) and O2D(AL)-S are general purpose oxygen analyzers for research, air separation monitoring, and industrial monitoring applications. Designed to measure oxygen in a range of 5-100% accurately and in the presence of other gasses such as including Ar, He, H2, CO2 and non-condensing H2O vapors. These models feature a sampling pump for flow control. The Model O2D(AL) and O2D(AL)-S features a high flow micro pump for low pressure operation from 1200 to 55mbar (0-60,000 feet altitude).

Features

Self-Calibrating Oxygen Analysis for Continuous Monitoring

The Model O2 D(AL), and D(AL)-S analyzers provide high-precision oxygen measurement designed for air separation, industrial gas production, aerospace research, and laboratory applications. Using laser diode absorption technology, these analyzers deliver ultra-fast response times, exceptional accuracy, and long-term stability for real-time oxygen purity monitoring. Their versatile design, multiple sampling options, and reliable performance make them essential tools for industries requiring continuous, high-purity oxygen analysis.

Optimized for Air Separation & Industrial Gas Production

The Model O2 D(AL), and D(AL)-S analyzers play a critical role in air separation and industrial gas applications, ensuring that oxygen purity meets precise specifications before distribution or further processing. These analyzers provide real-time monitoring of oxygen concentration in cryogenic air separation, membrane-based O₂ generation, and pressure swing adsorption (PSA) systems, optimizing efficiency and reducing losses.

Ultra-Fast Response Time for Process Control

With a sub-150 millisecond response time, these analyzers provide near-instantaneous oxygen concentration measurements, allowing quick adjustments in air separation plants, industrial gas pipelines, and aerospace test facilities. Rapid feedback ensures optimal process control and quality assurance.

High Accuracy and Long-Term Stability

Delivering oxygen concentration readings with ±0.2% accuracy, the Model O2 D(AL) and D(AL)-S analyzers ensure consistent and precise measurement over extended periods. Laser diode technology eliminates sensor drift, reducing the need for frequent recalibration and ensuring stable operation in continuous production environments.

Versatile Sampling for Air Separation & Industrial Applications

Designed for both extractive and inline sampling, these analyzers can measure oxygen concentrations in high-pressure pipelines, low-flow gas streams, and cryogenic systems. Their ability to operate in dynamic environments with variable gas compositions makes them ideal for air separation units, gas production facilities, and industrial quality control.

Multiple Output Options for Seamless System Integration

Equipped with analog (0-1V DC, 4-20mA) and digital (RS-232) outputs, the Model O2 D(AL), and D(AL)-S analyzers integrate effortlessly into air separation plants, industrial automation systems, and aerospace testing platforms. These flexible communication options enable real-time monitoring and remote system control, improving process efficiency and safety.

DAL-S: Enhanced with Swagelok® Fittings for Secure Connections

The DAL-S model includes Swagelok® fittings, providing high-integrity gas connections that enhance leak resistance, durability, and system reliability. This is particularly important in high-pressure industrial applications, cryogenic air separation, and aerospace environments, where minimizing leaks and ensuring a secure gas pathway is essential for measurement accuracy and system efficiency.

Technical Data